Shop

- PCB Repair

- Products

- Luxury sofa

- YIHUA 960-V90 Plastic Welding Kit Plastic Welder High Power with LED Light, 200 Hot Staples for Plastic Crack Repair, Car Bumper, Gas Tank Plastic Repair, Thicker Plastics, Car Dash Repair

Description

Price: $32.99 - $26.39

(as of Jan 04, 2025 03:06:37 UTC – Details)

Product Description

Fix Thicker Plastics Easily with the YIHUA 960-V90 Welding Kit

Welding Procedure

Clamp

Install the hot stable with a plier

Heat and Melt

Intersect with the crack, and melt into the plastic

Remove

Push the remaining staple left and right to snap off

LED Light

Enhanced VisibilityIlluminate for Precision WorkLow Light Friendly

Extra Hot Stapler Attachments

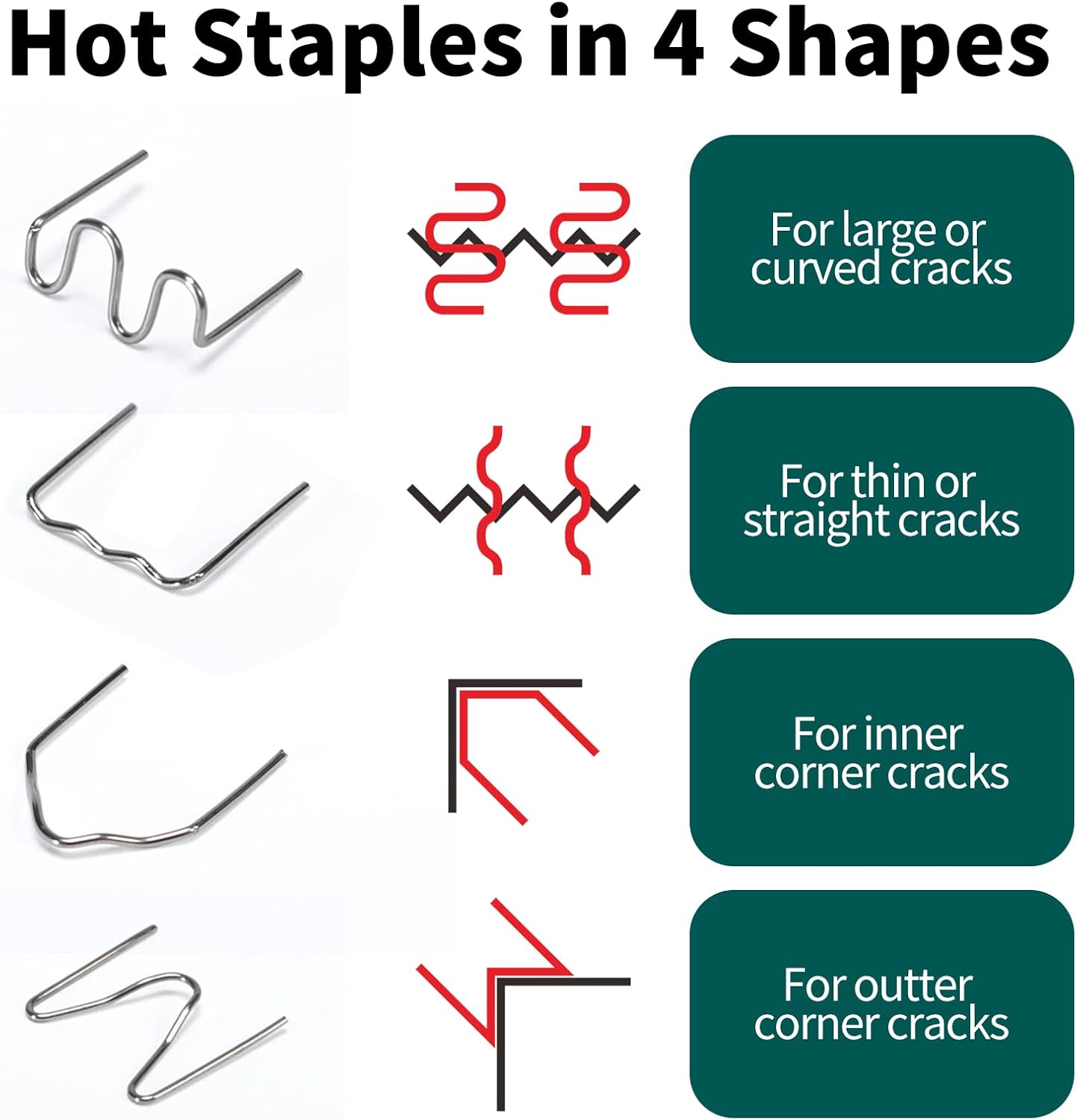

Diverse Selection: Staples for different crack types and sizes.Strong Bond: Melts into plastic for secure, lasting repairs.Wide Applications: Suitable for automotive, household, and DIY fixes.

Versatile Applications

Automotive Repairs

Car bumpersFendersOther plastic components

Motorcycle Restoration

Gas tanksFairingsWindshields

Household Fixes

FurnitureToysAppliances

Specifications

Model Number 960-V90 Rated Voltage Range 110V-127V/AC, 60Hz Rated Power 90W Dimensions L7.09*W6.69*H1.97in ±0.2in Operating Ambient Temperature 0~40°C/32°F~104°F

Thick Plastic Repair: The YIHUA 960-V90 Portable Plastic Welding Kit is perfect for plastic crack repair, car bumper restoration, gas tank mending, automotive mechanics fixes. This plastic welder is upgraded in power to work with thicker plastics effectively, provides greater heating power than the 50W models.

All-Inclusive Plastic Welding Kit: This plastic repair kit of plastic welding tools includes a built-in LED light for low-light workspace, 200 hot staples for different crack types (outer corner, inner corner, large/curved, thin/straight), and a staple trimer. With these welding tools, you can get started with plastic weld projects with our complete kit.

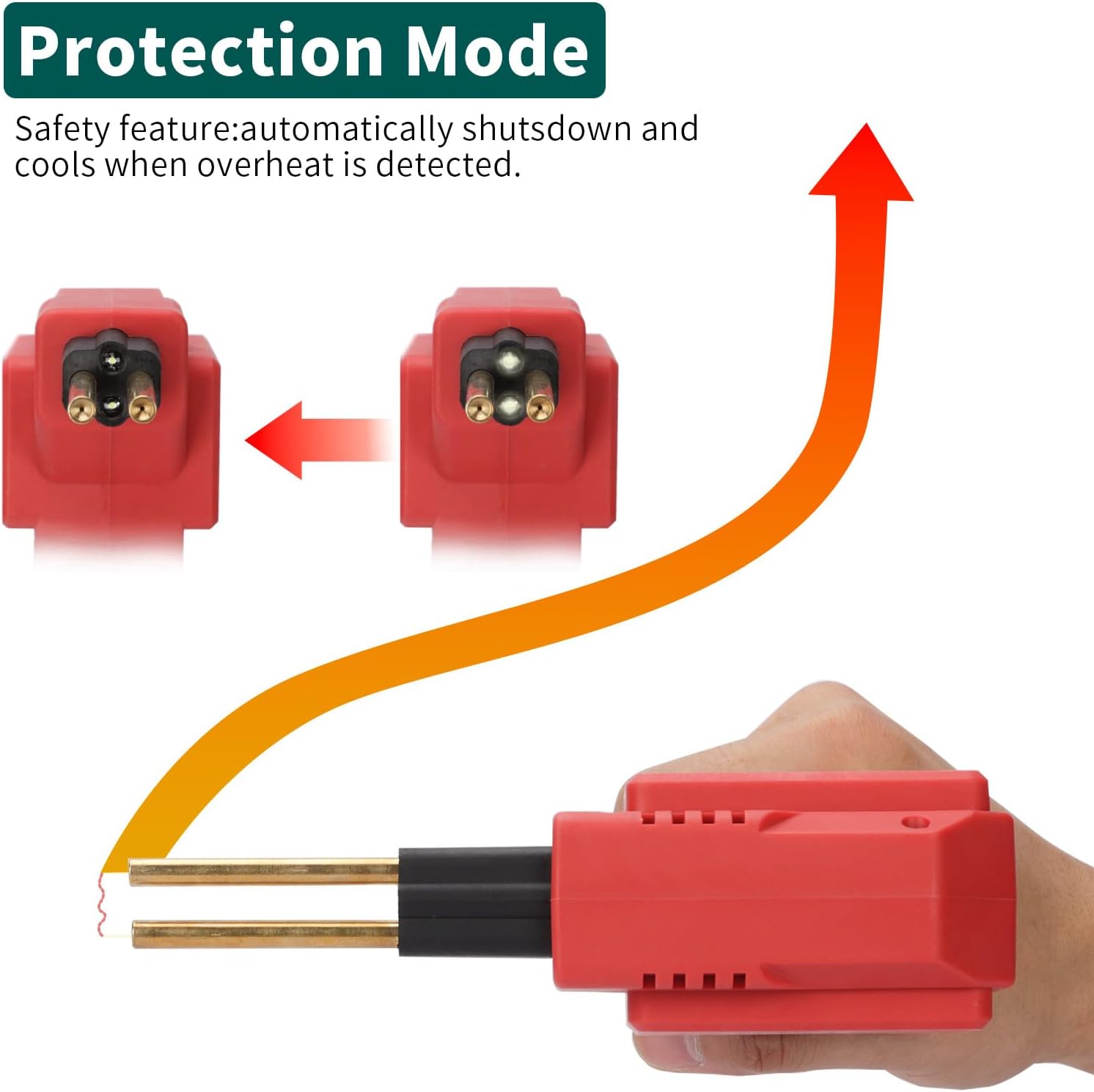

Advanced Safety: With the hot stapler’s auto shut-off feature, you can focus on your repair work, knowing that the plastic welder will automatically power down during extended periods of use, preventing potential accidents and damage due to overheating.

Straightforward Operation: The YIHUA 960-V90 Portable Plastic Welding Kit and welding tools offer fast heating and simple operation. Position the staple, press the activation trigger, and allow the staple to melt into the plastic. Separate the unit to reveal a clean, sturdy repair.

Choose YIHUA with Confidence – Enjoy our 12-month US- exclusive manufacturer technical coverage and 24/7 professional assistance on Amazon. Note: This model is designed to operate on 110-127V with a US-standard power plug.

SupplementJanuary 4, 2025

A chunky workhorse

I did some initial testing on some card gear and found that it was able to perfectly control the seams from the back out. If you are new to this sort of thing, I suggest you look at Youtube videos of it and get some insight into how you plan on using it. But for general home repair, and if you have a lot of plastic stuff laying around, it is essential hardware that I feel fewer people have than they should!With that said, this one is just a real workhorse – basic, but sturdy and effective. The price matches it and the quality matches it as well. I’m glad I have it!

Amazon CustomerJanuary 4, 2025

Works

I don’t use it a lot but it works, no complaints. Helps reinforce access holes that are patched after repair.

Kindle CustomerJanuary 4, 2025

Works great!

The only plastic crack I had was on the rim of my Gorilla Cart. The stapler looks tiny for a job like this but I was interested more in how the plastic welder worked. It heated up quickly. The staple melted right in with little pressure. The protruding ends broke off after a few back and forth bends without moving the staple. It worked as promised. I like it.

HawthorneJanuary 4, 2025

Works well, too easy to make plastic repairs!

I show a couple of pictures of the welder and it works real simple squeeze the button that’s black and it heats up a small shaped wire between the tips and it melts into a piece of plastic over both side of a crack, let it cool and presto it’s held together. It’s really that simple, I included in the picture a couple of tips that are specifically designed to smooth the plastic out over where it is cracked or broken. I did not get the smoothing tips with the welder!! the smoothing tips are not included with this welder!! I am just showing them so you understand what they look like if you are interested in doing plastic repair welding. I have also included a picture of the inside of my lawn tractor hood that was broken pretty bad and I was able to repair it real strong using just this machine and nothing more. As you can see in the pictures the welding wires I used and how well the crack was held together inside and out so the hood didn’t require anymore tips or replacement of the hood which saved me a large amount of money. I did do a little light sanding and if I had chose to a tiny bit of paint and this would not be obvious at all.

Holly W.January 4, 2025

Definitely needs a well-ventilated area

I got this to attempt to repair some tires on my kid’s UTV because the manufacturer no longer makes them, and it was a known issue. I have tried everything and thought maybe this would work. Nope, not this either the plastic is just too worn and thin.It has on the other hand fixed my broken Adirondack chair in two places and saved a few other odds and ends around the house and yard that have thicker plastic components.This mighty little device works great. The directions are simple, yet detailed. It comes with safety glasses and a whole slew of different shaped staples for each different angle of a plastic project.I’m certain that this kit is going to give new life to many things for my family for years to come. Just have to make sure that anything getting fixed is outside and there is at least a small breeze cause this smells that come off of that melting plastic cannot be healthy.

To3dJanuary 4, 2025

Would only work for short periods of time – UPDATE 12-15-2024

I used this to repair a plastic vacuum cleaner handle. I got a kit “Wrdlosy 1322PCS Plastic Welding Kit ” and used the ABS plastic rod and the included plastic welding tip to fusion weld the handle (basically like metal welding, melting the rod and the plastic pieces together after cutting a V-shaped groove into the plastic so that there was a cavity for the filler rod, just like metal welding).The welder would only heat for a few minutes before going cold. I would have to then wait for 5 or 10 minutes before I could go again. There was a second tip, and after the first quit working I put on the second and it seemed to work better. I noticed that a black residue would develop on the tips and I would scrape it off. Perhaps this is part of the reason, or perhaps there is issue with the Wrdlosy welding tips? My perception was that a heat safety switch was tripped after just a few minutes and that the gun had a very low duty cycle. But I’m not sure. At any rate the waiting was annoying.When the gun worked it worked well. The ergonomics were good, the LED light helpful, the trigger well positioned. But it was a challenge to finish my repair, which I eventually did. The repair is not aesthetically perfect, but the weld feels substantial. I didn’t fell the need to use the embedded plastic staples or mesh.My recommendation would be to look at other reviews and see if there is a pattern of the low duty cycle issue. It definitely killed my efficiency using the tool for the one repair I have done. I have a second repair coming up (John Deere cowl on a garden tractor). Hopefully I will have more data to report.Update12/16/2024================I used this for a 2nd repair, repairing the metal screen fastening onto the plastic windshield cowl of a Pontiac Vibe 2007. Rats or mice got into the ventilation system for a 2nd time and I was hired to clean it out. The plastic cowling under the windshield had some metal screening that had come partially loose and was filled with leaves and stuff. Possibly the rodents got into the ventilation system through here. I used the tool with the plastic welding tip from the “Wrdlosy 1322PCS Plastic Welding Kit” mentioned above. I used the PP (Polypropylene) rods. To verify the type of plastic I viewed the flow chart from the Polyvance website. I tested a few rods and the PP stuck well and appeared to be a match. I completely removed the wire mesh and reattached the mesh to the plastic cowling. The blobs were small, I added material and made the blobs bigger than original so looking at the cowl closely one could see the not perfect blobs holding the mesh from behind. One would have to look closely to notice, and the welds appear to be quite solid so I was satisfied with the repair. I also added HD wire mesh to the two inlets to the ventilation system using self-tapping screws. I can potentially add photos but am having issues with photo transfer from my phone so not right now.Here are my new findings about the YIHUA 960-V90 Plastic Welder. The tool is only 80 watts, so fusion welding is probably too arduous for it with any kind of decent duty cycle. I would recommend the upgraded 220 W version for not much more money. The welding tips from the “Wrdlosy 1322PCS Plastic Welding Kit” have issues in that one would work better than the other. I haven’t actually used this tool with the plastic staples, and probably 80 Watts would be enough for this. However, after using the tool and researching, plastic airless welding (fusion welding melting thermoplastics together) is a preferred method of plastic repair. The staples are mostly reinforcement, but still, one would want to fusion weld, or hot glue weld (like brazing, not true fusion welding, using a multipurpose plastic rod with glass reinforcement). One could use the wire stainless steel mesh that comes with the airless welding kits instead of staples. As stated, the staples are likely very good for reinforcement, and this YIHUA 960-V90 Plastic Welder is likely very good for that. But likely the SS wire mesh is just as good. The staples are probably easier for a quick and dirty repair, but there wouldn’t be any welding of the crack back together. I wouldn’t be satisfied with that personally…My next repair is going to be the polycarbonate hood of a John Deere Garden tractor. I am going to buy a pencil style solder iron plastic welder, at least 150 watts, or up to 200 watts. It is going to have temp control, either a 200 watt model with an analog (variac?) style voltage controller that is separate from the iron, or else a 150 watt unit that has a built in digital temp that likely just cycles the power on and off like the old style wall dimmers.The greatest challenge to plastic welding is identifying the type of plastic. I am going to get fiber flex style universal plastic welding rods that work with different types of plastic and are fiberglass reinforced. This makes it easier to identify the plastics. This type of rod is more of a hot melt glue rather than a true fusion weld. During my first foray, I used the ABS rods and that worked well. For my second foray I used the PP rods and that worked well. But I am curious about the universal fiber flex style rods. When identifying plastic do a test weld with a few different rods (should be able to narrow it down) and check to see which one sticks well and doesn’t peel off.