Shop

- PCB Repair

- Products

- Laboratory

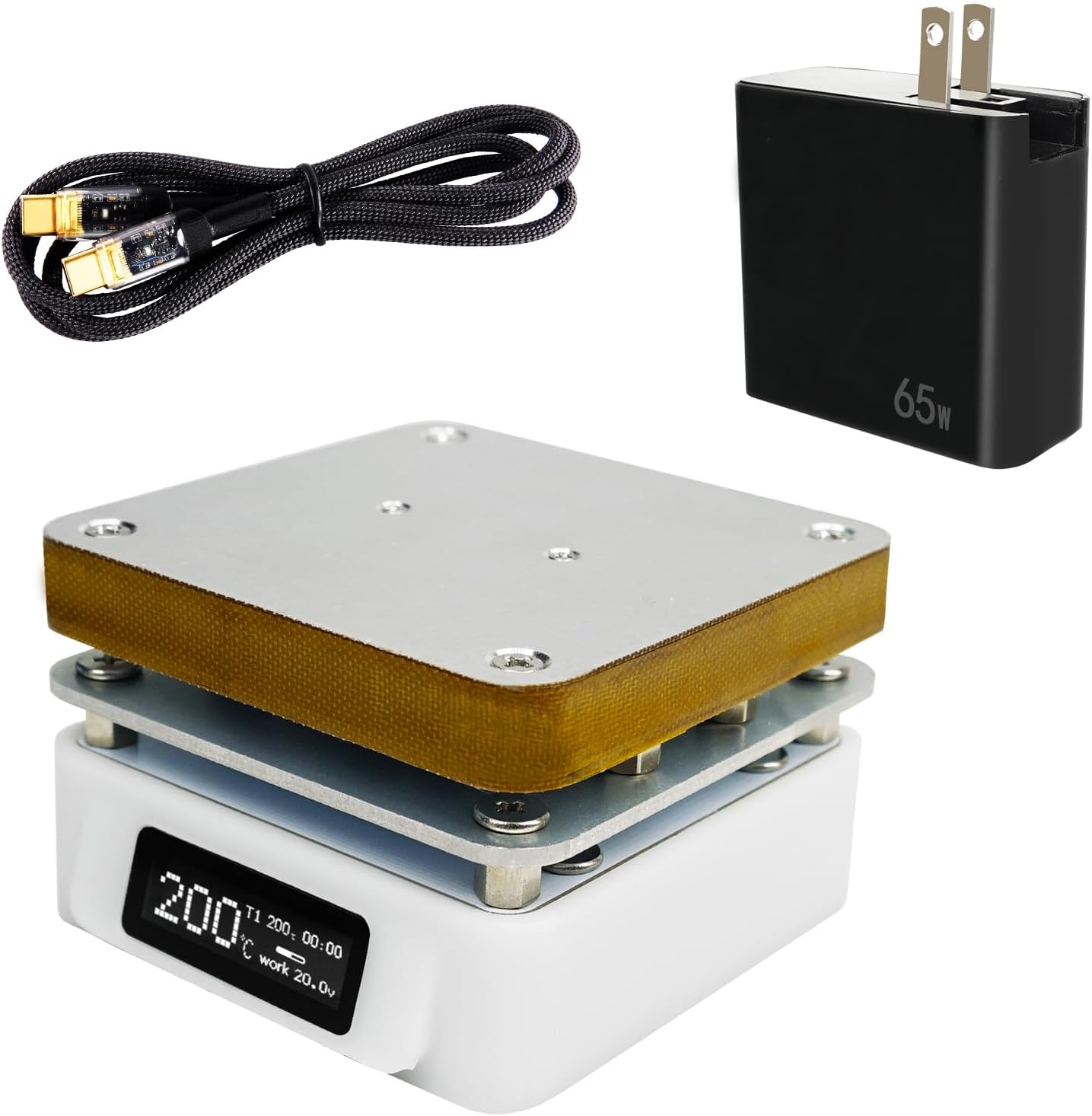

- Mini Soldering Hot Plate, 25V 95W OLED Electric Preheat Soldering Station, Rework Heater Lab 55MM x 55MM Plate (T55 + PD65W Power Supply + 100W 5A Fast Charging Cable)

Description

Price: $59.99 - $49.69

(as of Jan 30, 2025 09:32:13 UTC – Details)

Product Description

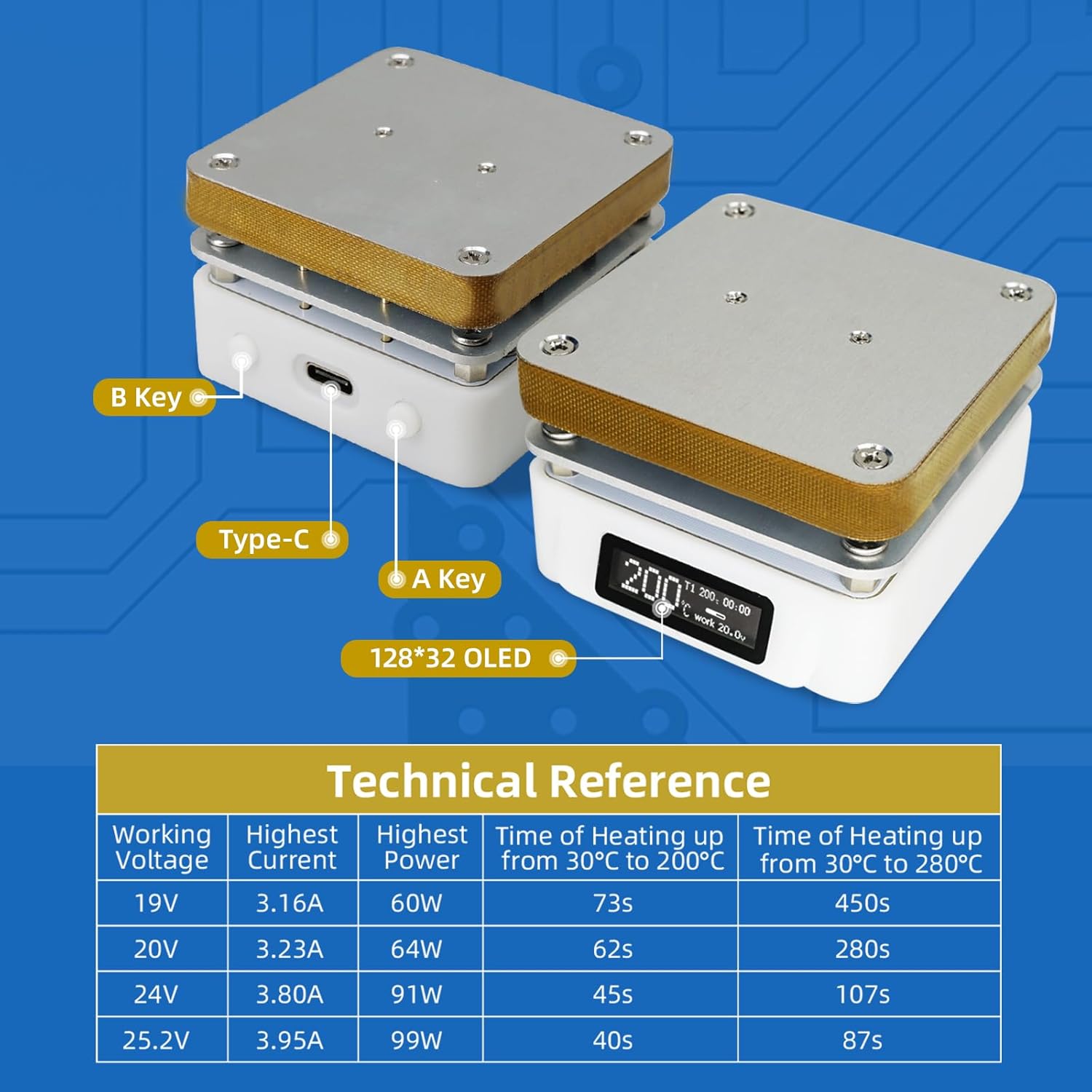

Specification of T55

Model: T55

Material: Aluminum

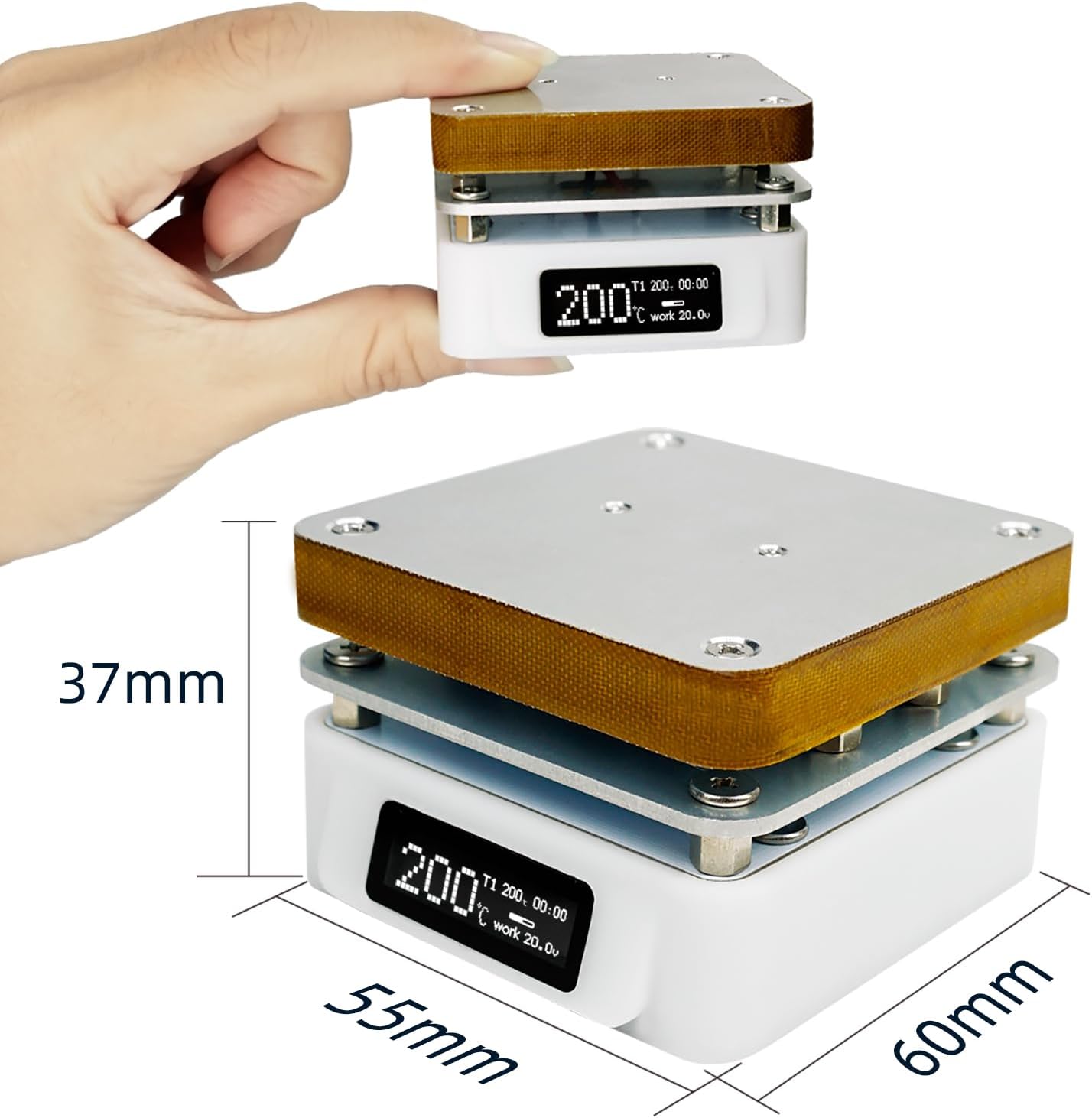

Size: 55 * 60 * 37mm / 2.1*2.4*1.5 inches

Heating Area: 55*55mm / 2.1*2.1 inches

Working Temperature: 50°C-280°C / 122℉-536℉

Highest Input Voltage: 25V

Highest Output Power: 95W

Recommend Input Voltage: 19V-25V

Power Supply Mode: PD, QC, DC

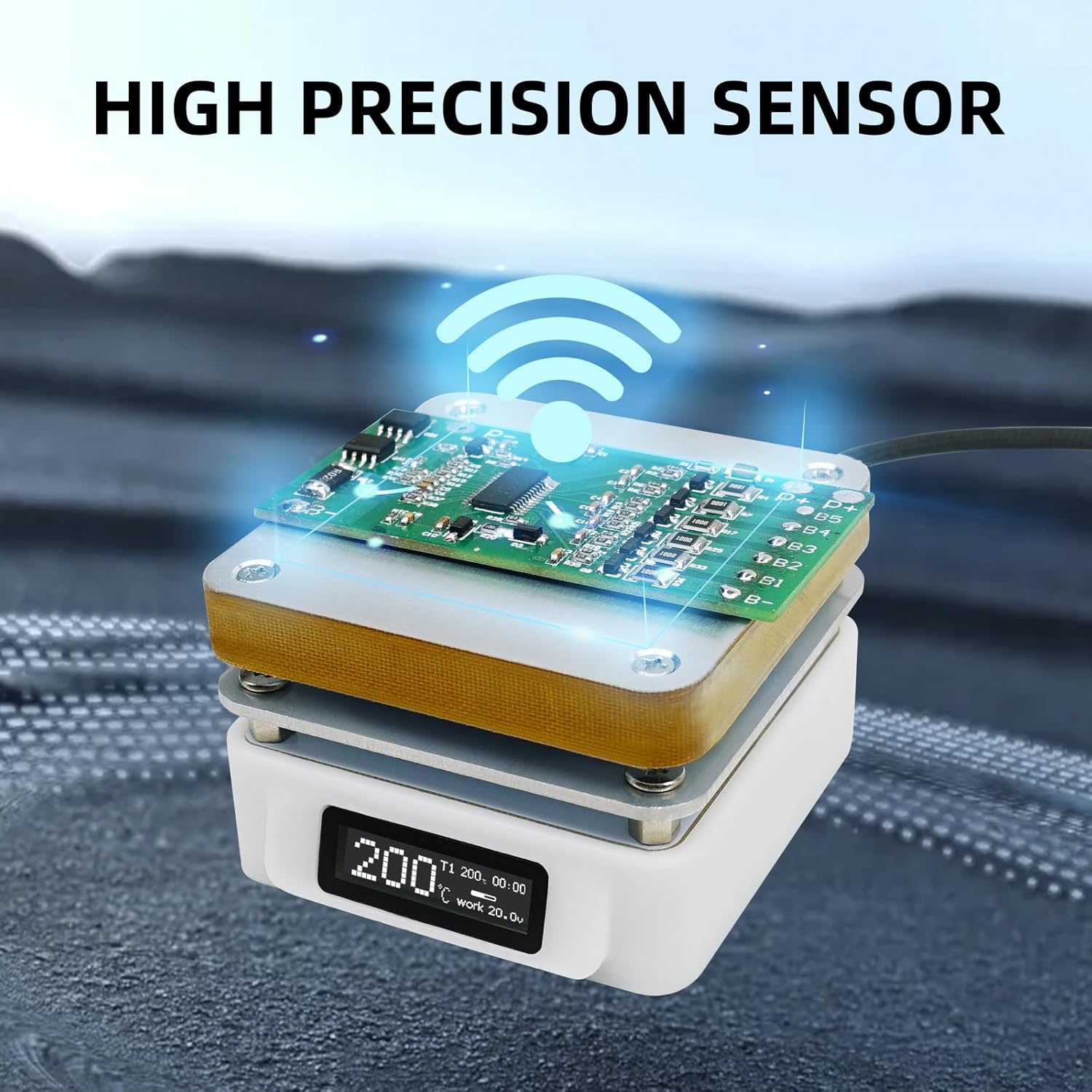

Built-in high precision temperature sensor, ensure high accuracy data measurement under continous high temperature.

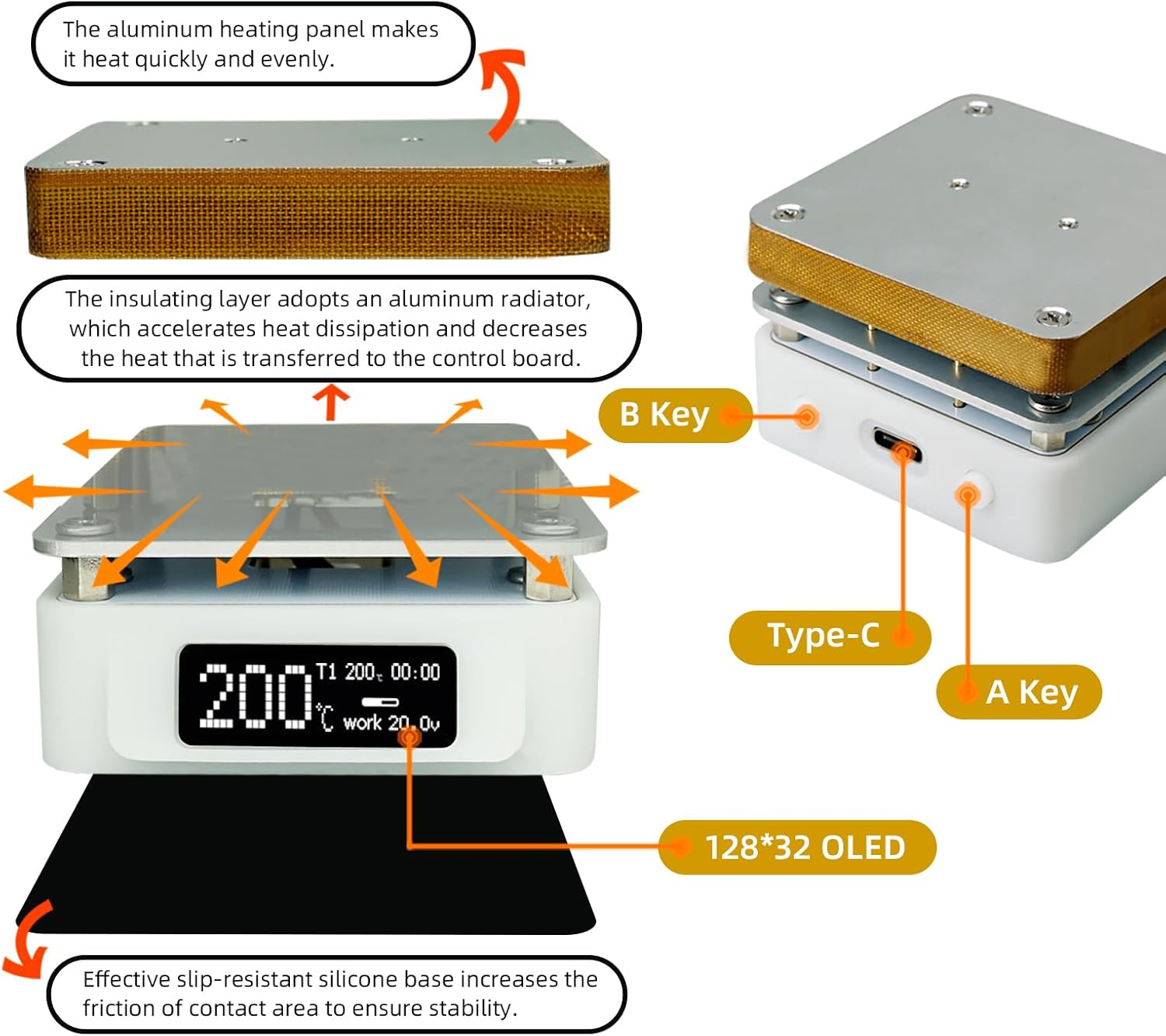

HD 128*32 OLED display, clearly show the data, easy & convenient to control temperature, and set the inner parameters.

Support upgrading firmware via computer, for a greater experience!

Aluminum heating panel makes T55 heat quickly and evenly. Heating Area is 55*55mm.

The insulating layer adopts aluminum radiator, which accelerates heat dissipation and descreases the heat that is transfered to the control board.

Slip-resistant base increases the friction of contact area to ensure stability.

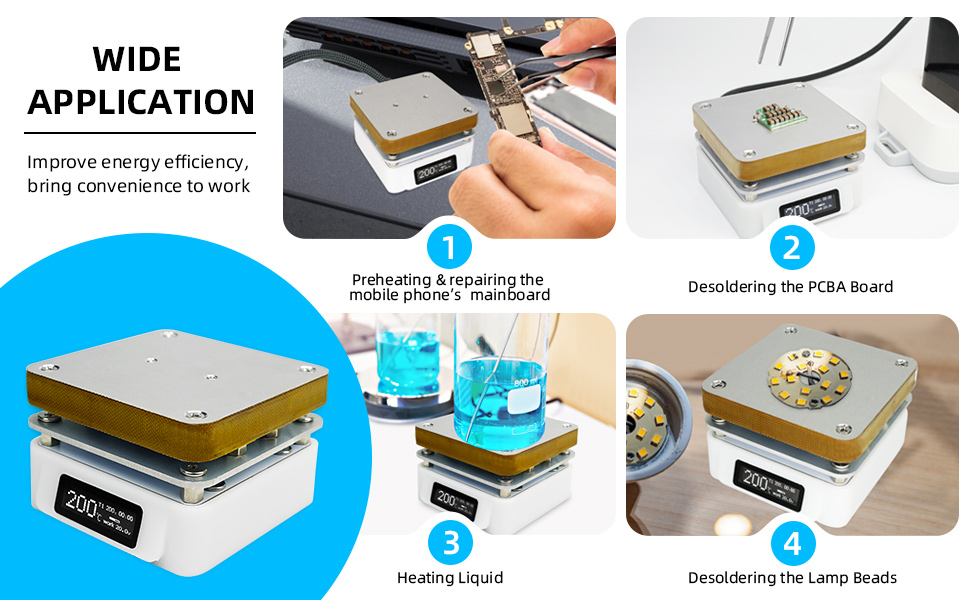

【High Efficiency】 T55 preheating station equipped with aluminum radiator for high thermal efficiency. When using a 65W PD power supply under 25.2V, it only takes 87 seconds to heat from 30°C to 280°C. Working temp range: 50°C-280°C.

【Small but Powerful】 Mini & lightweight soldering hot plate with a heating area of 50 x 50mm. Adopts high-quality aluminum plate as a heating element, T55 transfers heat faster and more uniform.

【Multi-functions】 Preset temperature, time heating, automatic sleep, compensate temperature, multi-language menu, and firmware upgrade.

【More User-friendly】 The heater is equipped with an OLED display and two physical buttons(on the back), easily control & adjust temp. Slip-resistant silicone base to ensure stability.

【Wide Application】 This hot plate can be used on the workbench or out in the field, preheating & heating & desoldering circuit boards, components, LED beads, etc.

Customers say

Customers find the soldering station functional and effective for heating small boards. They appreciate that it works well and provides good heat retention.

AI-generated from the text of customer reviews

SecretReviewerJanuary 30, 2025

I have used a thermal camera on this and it’s accurate.

The drift between set temperature and actual temperature below 400 F was only a few degrees (like, 5), whereas it started to become a little more noticeable above 400. Above 400, it was still within 15 of the set temperature which is pretty amazing.It’s much smaller than you’d think, but it’s very cute and functional. I used it to open a watch – that’s the perfect size for this hot plate.

Robert A., Philadelphia, PAJanuary 30, 2025

Does its job, but no programming multi-step profiles.

This little hot plate does a good job flowing SMD components on printed circuit boards.If you want a specific heating/cooling profile, you’ll need to do it manually if using this hot plate.It has a small, but easily read, graphics display that continually updates the status of the unit. It also displays the menus and values for editing.There are two buttons on the unit for controlling the unit ,navigating the menus, and changing values and operating modes.Programming the temperatures in the three on-board setpoint memories (and changing the other parameters) is fiddly unless you have the procedure well memorized, because if you pause more than 5 seconds (while looking at the manual) the current menu jumps back to the previous menu automatically. It will continue to do this , every 5 seconds, until it reaches the operating screen on top, unless there is another button press. There are only two buttons on the unit, so I guess there was no way to manually back out of the menus and still be able to navigate and edit the values.A PDF operation manual is available for download from their website that explains setup and the menus. I think it could have been better (but then I used to write training manuals), but it is better than most that come out of China and it does show the intire menu system.The plate is 55mm (2-3/8″) square, which is fine for mobile phone and other small circuit boards. It could also be used for spot reflowing on larger PCBs. It could also be used for reballing the PCB grid for BGA ICs.All in all not bad, considering it is 25%-30% the cost of the original mini hot plate.The wall wart that comes with the hot plate works fine. The fact that it doesn’t heat up as fast as two other, higher current models (available as options), is actually a plus as this keeps from thermally shocking the circuit board by heating it up too quickly. You do have to use their wall wart as it provides multiple voltages to the hot plate.The supplied “USB” cable has some smarts built in too, along with an idicator showing that power is applied.If you want to see a third-party demo of this unit, check out ‘IMSAI Guy’ on YouTube.

GnarlykatJanuary 30, 2025

Highly recommended for small boards

This along with hot tweezers are mandatory for small project or (hobby) repair work.

JGJanuary 30, 2025

Works great!

Needs a USB-PD power supply that can do 20V 3A. Several of my smaller power supplies just go into overcurrent shutoff when it tries to heat. A 100W laptop supply works well.The user interface is a bit awkward, but it works. I wish I could program in a temperature profile with precise timing.Smells like feet. Weird, but okay.

SteveJanuary 30, 2025

Small boards or pieces of boards for disassembly

What I expected, heats well. Will use for SMD soldering or stripping boards of reusable parts.

Leonardo e acostaJanuary 30, 2025

Tech

Didnât work for me

Kenny ManchesterJanuary 30, 2025

A well-made hotplate perfect for small PCB repairs and rework.

This mighty little hot plate is very well-built and does exactly what it is supposed to do. It heats up smaller PCBs (electronic circuit boards) in my case very well allowing me to more easily perform repairs by replacing small SMD components that failed or remove them in order to test them. Most of my repairs are on larger circuit boards, but this can sometimes be used to concentrate heat to the back of a large PCB in a focused manner too. Can you use a hotair rework station instead? Well, I would have to say yes, but a hotplate is much less likely to feel like juggling and you can keep your eyes completely on the part you’re removing or reflowing. I’d recommend this to anyone who does rework and repairs on electronic circuit boards. It’s a nice tool to have around when you need it.

Brett ClintonJanuary 30, 2025

Works great

Works exactly as expected used it to fix a motherboard for my Xbox